EBICO empowers the first petroleum refining project in Laos

EBICO empowers the first petroleum refining project in Laos

Recently, the online production ceremonies of the first phase of Laos’ first petroleum refining and chemical project were held in Vientiane and Kunming respectively. The EBICO ultra-low nitrogen burner matched with the 35-ton Anshan boiler as the core heating equipment of the project enabled the smooth operation of the project. Song Sai, member of the Political Bureau of the Central Political Bureau of the Lao People’s Revolutionary Party, Deputy Prime Minister and Minister of Planning and Investment, Jiang Zaidong, Chinese Ambassador to Laos, and others at the Laos venue, and Wang Yubo, Acting Governor of Yunnan Province, and others at the Yunnan venue to witness the Lao Petrochemical Co., Ltd. 3 million The first phase of the refining and chemical project per ton/year was put into operation.

The 3 million tons/year refining and chemical project of Lao Petrochemical Co., Ltd. is located in the Saiseta Comprehensive Development Zone in Vientiane, Laos. It covers an area of 425 mu and plans to invest about 2 billion US dollars. It will build a modern oil refinery that meets the standards in three phases. It is reported that the comprehensive processing capacity of the Lao Petrochemical Phase I project will reach 1 million tons per year. After being put into operation, it can produce gasoline, diesel, aviation kerosene, liquefied petroleum gas, industrial sulfur, and other products that meet the Euro V standard every year, providing Laos with a safe and stable supply of refined oil.

The “Belt and Road” project has become a new milestone in China-Laos cooperation. The completion of the project will effectively fill the gap in Laos’ petrochemical industry, reverse the situation that its refined oil can only rely on imports, and play an important role in Laos’ industrial development and construction of the chemical system.

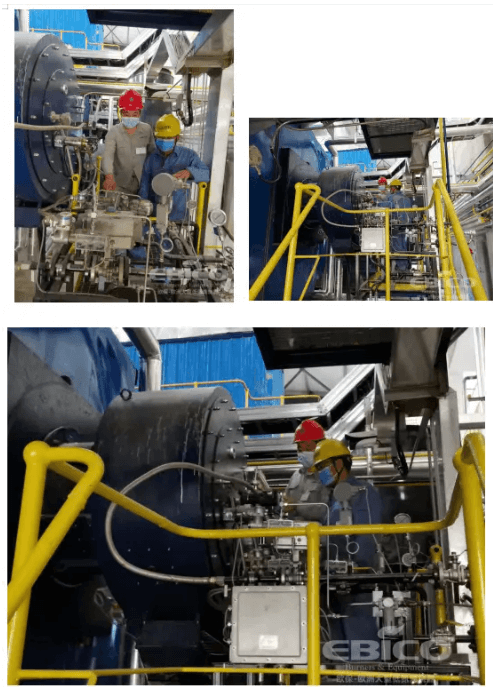

The target boiler of this project is 35T, and the main fuel is fuel gas (gaseous state) produced by the refinery and diesel (V) for vehicles. The user requires that the matching burner must be able to burn 100% of a single fuel or 100% of another fuel. At the same time, it meets the user’s requirements for co-firing: but the fuel load during co-firing is not less than 20% of the boiler load, and the gas load is not less than 15% of the boiler’s load. That is to say, on the basis of ensuring extremely high combustion efficiency and extremely strong combustion stability, the burner must be able to achieve single-burning oil, single-burning gas, fixed oil-adjusted gas mixed-burning, and fixed-gas-adjusted oil mixed-burning four. mode. Needless to say, the requirements for the matching burner are very high. EBICO rose to the challenge. According to the actual working conditions of the project, it was equipped with two EBICO EC12GGQR series split burners, 6-120 t boilers, power 5580-33500KW, and electronic proportional adjustment.

Under the haze of the epidemic, EBICO’s professional technical team still adhered to the overseas front-line commissioning site providing Laos with on-site technical support for a period of 51 days from October 13th to December 2nd and tracked and controlled online monitoring data on the spot. The smooth production will be escorted, and the follow-up EBICO will provide technical guidance services for the project at any time.

As a pioneer in the development of industry technology, EBICO has gone deep into the overseas front line, contributing to the development of renewable energy strategies and jointly creating a new highlight of China-Laos cooperation!

EBICO, integrating the concept of European design and China’s 2025 intelligent manufacturing alliance, strives to build the world’s leading EBICO brand and its safety, environmental protection, energy-saving, and intelligent system, combining the most advanced technology, the most competitive manufacturing, the most Timely service is presented to Chinese customers, and meets users’ most critical vision, strictest emissions, and safest configuration requirements.